and the distribution of digital products.

From Resistance to Resilience: Change Management for First-timers in Digital Transformation

In my previous article, I discussed the role of data translators in bridging the communication gap between the business and the technology teams by turning complex data analysis into actionable insights that drive enterprise success. While data translators hold the power to unlock the potential of advanced technology, translating data is only part of the equation. For these data insights to drive real business impact, they must inspire action, which demands a shift in how people across the business work. From my own experience, even the best technology or insights fail to reach their potential without a deliberate approach to change management. The greatest challenge in digital transformation is often less about the technology and more about transforming operating models, mindsets, and behaviors to create meaningful, lasting impact. Without change management, digital transformation is just an unfulfilled promise.

\

Why Digital Transformation Can’t Take Place Without Change Management\ Digital transformation is often framed as a technological challenge, though it’s ultimately a human one. For organizations which are used to living by manual processes and siloed workflows, introducing automation and digital tools can feel disruptive. Resistance isn’t the enemy but rather a sign for a deeper need for change. Having led the rollout of a digital system for the end-to-end trading card production at our sports commerce company, I realized that the true measure of success wasn’t the technology advancement but the adoption, usage, and organizational impact inherited from this technology. It is undeniable that change management is key to evolving our legacy systems into modern, efficient processes that enhance operational efficiency and drive greater profitability across all our business teams. The journey taught us that the success of digital transformation can only be recognized through acknowledging that people, not technology, are the true drivers of change.

\ At our company, the card production process relies on offline documents and manual processes as the primary source of truth. There is no centralized system to track key product statuses or timelines and manual workflows frequently prolong review cycles, increase errors, and hinder our scalability. To address these inefficiencies, we built a modern digital system to centralize product data, improve visibility into development progress, streamline production workflows, and reduce repetitive tasks. However, transitioning from a decade-long legacy system requires more than just technological upgrade. It demands effective change management to reimagine outdated processes and overcome cultural resistance.

\

How Our Change Management Strategies Overcame Legacy Challenges\ To navigate this change, I helped establish a change management initiative rooted in Kotter’s 8-Step Change Model. By cultivating a sense of urgency, empowering cross-functional collaboration, and fostering incremental adoption, I led the team in uprooting deeply rooted habits to open up to novel changes:

\

Addressing Cross-Team Systems and Workflow Interdependencies

\

Drawing from Step 5: Empowering Broad-Based Action in Kotter’s model, we designed testing to mirror real-life workflow interactions across various teams, which addresses critical touchpoints that enable task hands-offs from one team to another. For example, the Project Management team relies on inputs from Product Development, Design, and Finance teams to track the status of tasks across product groups, subsets, and cards. Failing to account for these linkages in our new workflow would hinder the system's potential, risking status delays and workflow disruptions that hinder the new tool from realizing its full benefits.

\ As such, we designed our testing programs to ensure the new system could integrate data and processes from one group to another. We included end-to-end testing of key milestones, validation of data integrity across workstreams, and iterative feedback loops to refine these functionality. By involving representatives from each team, we ensured the system supported collaborative workflows and addressed real-world challenges, thereby driving alignment and operational efficiency comprehensively.

\ We carefully selected pilot products and projects to span different stages and components of the workflow, helping stakeholders understand how their roles influenced the broader processes. For example, the same products were chosen for testing across various teams to ensure that output from one team correctly flowed into the next as input. This approach allowed the refinement of workflows and addressed gaps proactively, ensuring that the new system accounts for the end-to-end production process instead of one isolated step.

\ We designed user guides and demo videos to emphasize cross-workflow features such as real-time updates, automated notifications, and conflict alerts. These materials incorporated feedback from pilot testing and showcased practical scenarios, helping teams visualize how the new system could improve their daily tasks. By focusing on these features and their tangible benefits, we fostered a sense of shared ownership and underscored the importance of cross-team functionality in letting the new technology drive the new system.

\ Case study example: A similar approach was adopted by Ford Motor Company during the launch of the new F-150. Ford addressed siloed operations by leveraging strategic research, ethnographies, and cultural anthropology to create cross-functional and diverse workflows that strengthened connections between design, engineering, and manufacturing teams. This strategy enabled Ford to align around the customer, adopt innovative ways of working, make strategic decisions, and foster continuous innovation, ultimately achieving remarkable success with the launch of the new F-150.

\

Making Testing “Real” Through Hands-On Practice

\

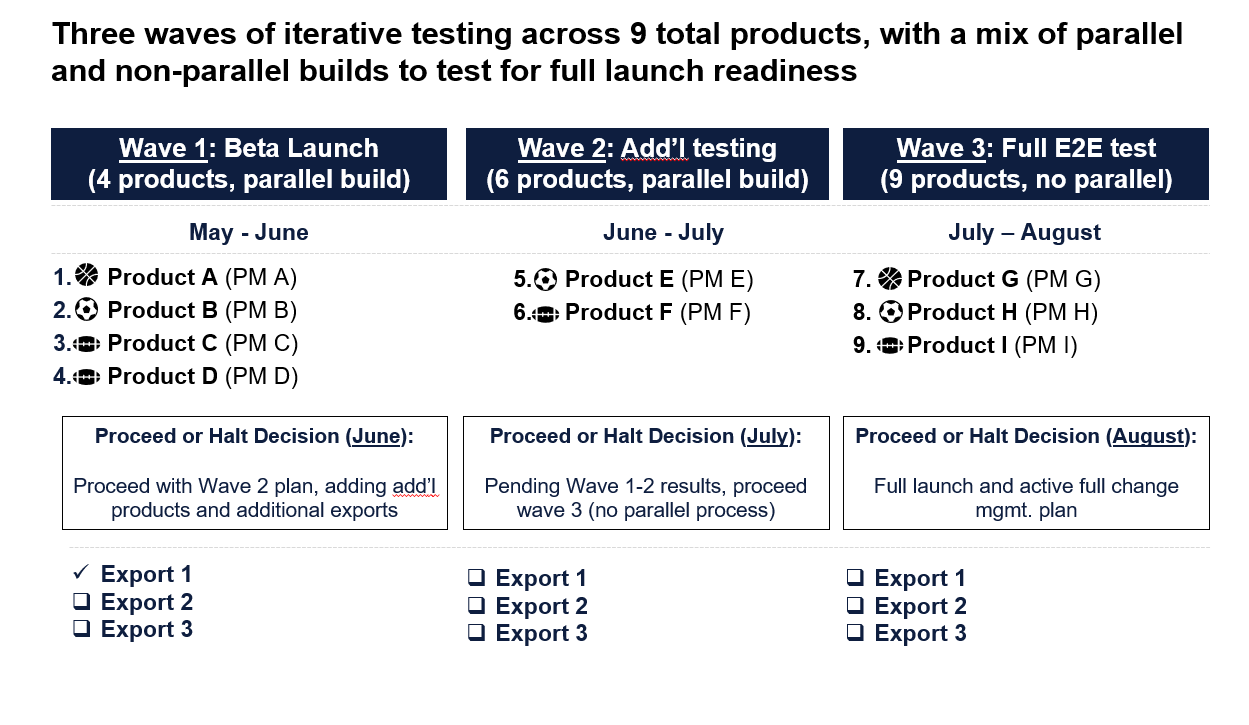

Building on Step 6: Generating Short-Term Wins in Kotter’s model, we prioritized early hands-on practice to build momentum for broader adoption. Through a multi-phase pilot program, teams had the opportunity to engage with the new system in real-time and test a comprehensive range of use cases to proactively address challenges that could arise post adoption. Each phase simulated different edge cases that occur during the end-to-end production process, such as product change request submissions post planning or updates in product designs that affect downstream printing. This enabled teams to experience how the new workflow operated in realistic scenarios and build confidence in the system’s capabilities.

\

**

For example, during testing, we discovered bottlenecks in creating various scenarios of scheduling projections. To address this, we introduced calculated fields for task scheduling to ensure better accuracy. This approach enhanced user confidence through allowing users to create accurate projections of different operational scenarios that allow them to anticipate and act on a range of outcomes. By allowing teams to practice in a low-pressure environment, we were able to identify areas for improvement in the process and allow teams to become accustomed to both the new system and workflow, thereby reducing resistance and enhancing adoption. Feedback loops after every phase further helped us align the system with team needs, thereby reinforcing trust and adoption in business users.

\ Case study example: A notable example of a company employing a multi-phase pilot program to assess system readiness and build early enhancements to facilitate wider adoption is Avangrid, Inc. In August 2023, Avangrid initiated a pilot project with LineVision, Inc. to enhance grid capacity in New York State. Avangrid piloted LineVision's Dynamic Line Rating (DLR) technology on select transmission lines in New York to evaluate its performance in real-world conditions. This approach enabled them to test the system's reliability and incorporate feedback from engineers and grid operators to resolve data integration bottlenecks with their existing grid management systems. Early solutions included developing middleware for seamless data flow, implementing real-time monitoring dashboards to highlight system discrepancies, and automating data mapping and validation to minimize manual errors. By resolving these issues early, they ensured a smoother and more effective full-scale rollout.

\

Ensuring a Smooth Transition with Phased Rollout

\

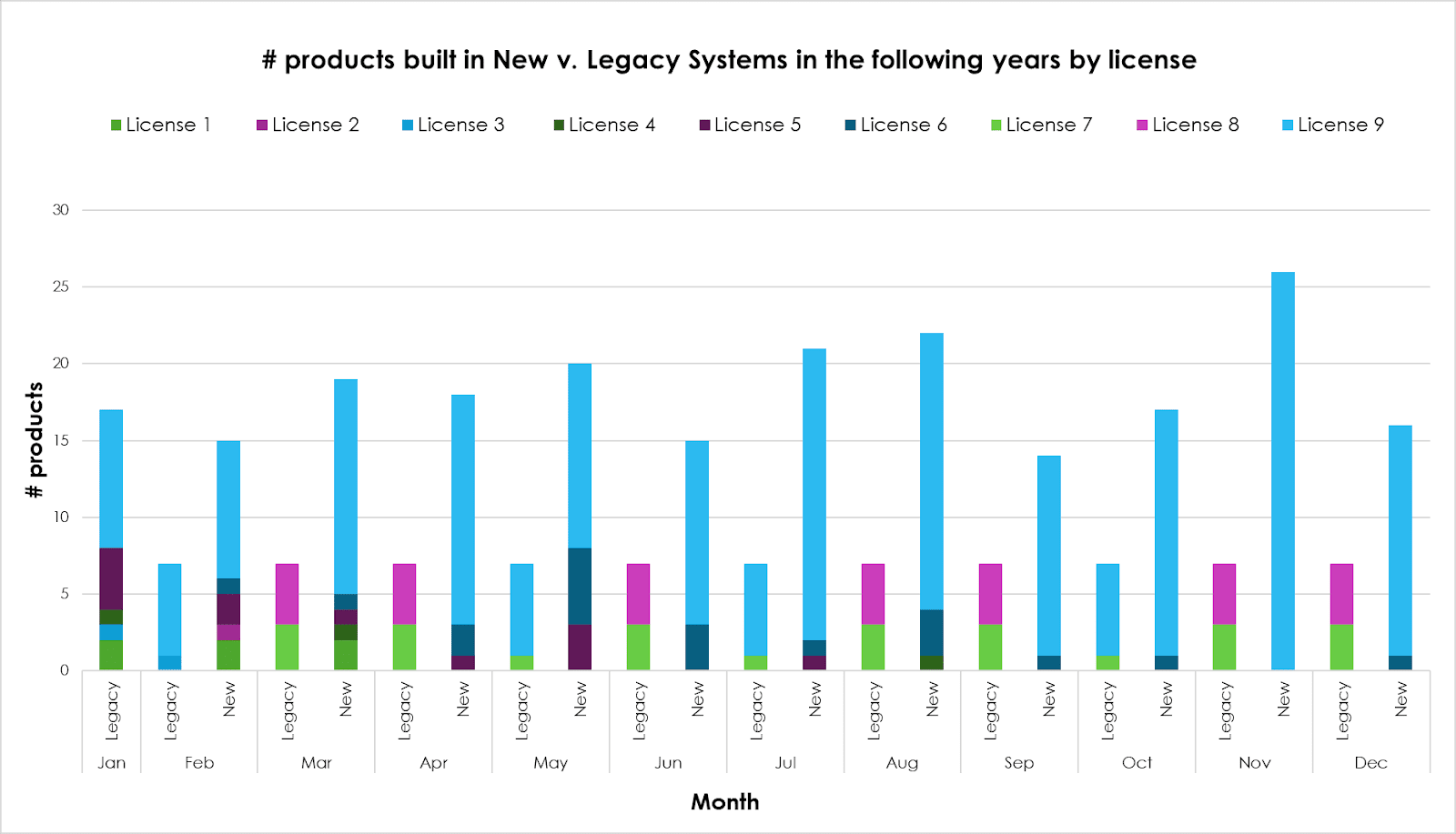

Following Step 7: Consolidating Gains and Producing More Change in Kotter’s model, we took an iterative approach to the system rollout, building on early successes and refining the processes across various stages. We began with launching the system across North American products, then gradually expanding to the full suite of international products and selected card licenses for built based on business value and technical feasibility.

\ The order in which these card licenses were built were prioritized based on their revenue size, ease of data integration for card’s athletes information, and production complexity. We started with high-revenue team sports before moving to individual sports which comprised a smaller portion of the product portfolio and required more technical configuration. This phased approach minimized workflow disruption, gave teams time to adapt to the new tool and workflow, and allowed us to address challenges in real-time. More importantly, it enabled a comprehensive and forward-looking rollout plan across all card licenses and regional product lines by prioritizing the feasibility of building products based on existing features and the available bandwidth of the new system. This approach allowed for strategic planning of features and workload capabilities for future system versions.

\

**

Case study example: A similar strategy was employed by IBM during its transformation from selling hardware to delivering customer solutions. IBM targeted pilot projects in specific departments, such as consulting services and outsourcing, to test new frameworks and workflows. These pilots allowed IBM to identify bottlenecks, refine its opportunity management process, and address resistance early. By focusing on scalable successes and engaging top talent as change ambassadors, IBM built momentum that supported the company-wide rollout of its new business model.

\

Transforming Challenges Into Growth\ By leveraging Kotter’s 8-Step Change Model, we successfully developed a robust change management program for our first enterprise-wide digital transformation. This approach addressed cross-workflow dependencies, facilitated early hands-on system testing and learning, and emphasized an iterative rollout over a high-risk, big-bang implementation. For organizations embarking on similar journeys, resources like the Harvard Business Review’s Managing Change Insight Center offer valuable strategies and actionable insights for navigating complex transformations. These tools proved invaluable for first-timers like us, ensuring a smoother transition and laying the groundwork for sustainable change.

- Home

- About Us

- Write For Us / Submit Content

- Advertising And Affiliates

- Feeds And Syndication

- Contact Us

- Login

- Privacy

All Rights Reserved. Copyright , Central Coast Communications, Inc.